Lean and Mean

AR & VR leads the way in Lean Manufacturing

The lean concept of manufacturing goes back to Toyota in the 1950’s, and is the effect of efficiency on the manufacturing process. Much of the efficacy comes through proper training and planning. The industries that have benefited the most from lean processes are manufacturing, and construction. Both of these industries are finding that VR and AR technology helps them achieve their goals to complete projects in less time and save money.

A recent paper in Advances in Manufacturing II, titled AR and VR in Lean Manufacturing Classes the authors discuss applications of VR and AR as a tool in teaching students how to effectively and efficiently implement lean principles into the manufacturing of a simple object built of LEGO blocks. Whether it is using VR in a design process, or AR to guide assembly, the research showed a substantial improvement in efficiency using VR and AR technology, versus a traditional system of paper plans and instructions.

VR allows the opportunity to work in a true 3D environment during the design, and prototyping process. It gives the design team the ability to hold and manipulate parts in a way that was only possible through physical model making. The advantage of VR is that flaws in the design can be discovered and addressed efficiently, without the wasted iterations and capital needed to make a physical model and reveal the same flaw. Lean processes dramatically cut the time and cost of the design and prototyping process, allowing the design team to hit KPIs resulting in a much higher efficiency and ability to develop faster.

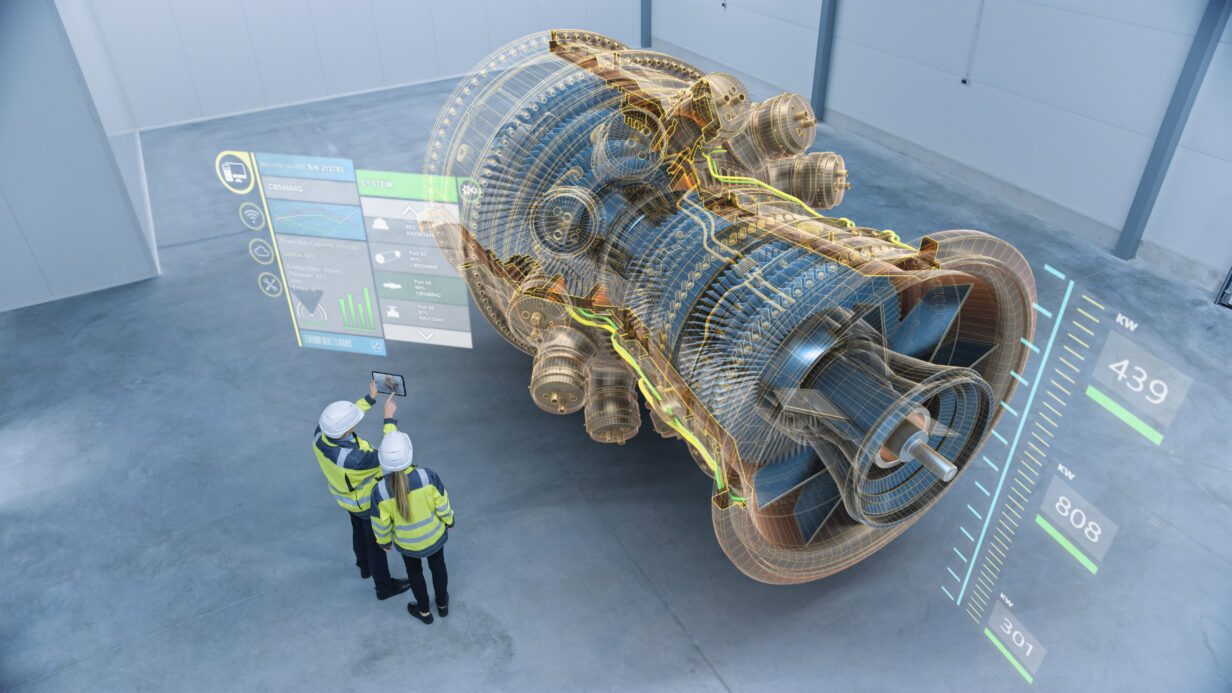

Augmented Reality (AR) improves the manufacturing process by training line workers on a physical line, using the machinery they will be working with on a day to day basis. Seeing details of the process overlaid onto the actual equipment allows the worker to safely learn a new system, while simultaneously developing a comfort level not available in a classroom observation environment.

AR is the hottest new tool for field technicians because it allows schematics to be overlaid directly over the equipment being serviced, providing for a more effective service call.

In the manufacturing sector, VR and AR are the tools for massive gains in productivity and reduction in the time to market for new products. Designers and production teams drastically cut costs, reduced the number of prototyping iterations and surpassed the competition with lean manufacturing strategies.

— Don Group is the Director of Business Development at CodeReal and can be reached at don@codereal.io